- Interchangeable with cPCI COTS Systems

- Immune to shock and vibration fretting

- High-temp LCP insulator meets NASA outgassing requirements

- Reverse Gender to commercial 2mm Products

- Keying feature ensures proper mating

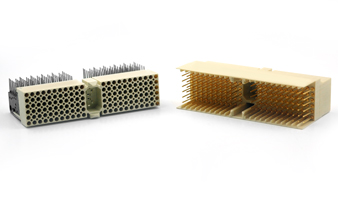

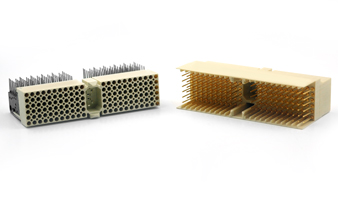

Smiths Interconnect cPCI 2mm connector system is based on the legendary Hypertac® contact technology, which is known for its’ immunity to shock and vibration fretting. Tested to military standards, the cPCI 2mm connector delivers the highest performance in a ruggedized CompactPCI format for all mission critical applications such as military land systems, shipboard, and aerospace.

Configured on a 2mm center-line with six rows, this connector uses 0.4mm Hypertac contacts that feature less than eight milliohms of contact resistance and a current rating of 1.0A. Our optimized contact lead traces provide superior performance in high-speed signal applications, and these connectors are compatible with standard reflow soldering processes.

The cPCI 2mm connector is available in both keyed and unkeyed configurations. Modular in design, the connector is variable in length and can be changed in increments of five contacts.

Other benefits include:

Hypertac contacts provide high reliability

Standard 2mm footprint

Shield prevents EMI/RFI

| Q CI (Quality Conformance Inspections) K2 Series = MIL-DTL-55302 311P Series = NASA GSFC S-311-P-822 |

||||||

| 3U/6U Form Factor | P1/P4 | P2/P5 | P3 | J1/J4 | J2/J5 | J3 |

| Part Number Reference | K2A110FMD | K2B110FMD | K2B095FMD | K2A110FFD | K2B110FFD | K2B095FFD |

| Design Criteria | IEC 1076-4 101 | |||||

| Contact Gender | Male Pin | Hypertac 0.40mm socket | ||||

| Contact Termination | Solder tail 63/37 tin lead plated | Gold or 63/37 tin lead dipped | ||||

| Contact Spacing | 2.00mm | |||||

| Number of Contacts |

110 signal

22 ground

|

95 signal 19 ground |

110 signal 22 ground |

95 signal

19 ground

|

||

| Contact Current Rating | 1 Amp | |||||

| Temperature Range | -55° C to 125° C | |||||

| Insulator Material | 30% Glass Filled LCP (meets NASA outgassing specification) | |||||

| Flammability Rating | 94 V-O | |||||

| Insulation Resistance | > 5000 megohm | |||||

| Contact Material | Beryllium copper pin contacts | Beryllium copper Hypertac socket wires and brass body | ||||

| Mating Contact Plating |

50µin gold / 50µin nickel min.

|

|||||

| Max. Allowable Gap Between Mating Connectors | 0.039 inches [1.00mm] | |||||

| Suggested PCB Hole Diameter |

0.71±.05 mm after plating | 0.60mm after plating | ||||

| Weight | 0.55 oz | 0.53 oz. | 0.38 oz. | 0.38 oz. | 0.45 oz. | 0.31 oz. |

| 3U/6U Form Factor | P1/P4 | P2/P5 | P3 | J1/J4 | J2/J5 | J3 | |

| Part Number Reference | K2A110FMD | K2B110FMD | K2B95FMD | K2A110FFD | K2B110FFD | K2B95FFD | |

| LLCR (Low Level Contact Resistance) | 7.20 milliohms average | ||||||

| DWV (Dielectric Withstanding Voltage) | 1000 VRMS | ||||||

| Contact Life (Mate/Demate) | >4000 Cycles (per mated connector pair) | ||||||

| Mating Force | 16.38 LBF average (per mated connector pair) | ||||||

| Demating Force | 13.2 LBF average (per mated connector pair) | ||||||

| Vibration (Sinusoidal)* | Frequency 10 to 2000 HZ at 15G (MIL-DTL-55302) (NASA GSFCS311-P-822) | ||||||

| Vibration (Random)** | Flight chassis unit level vibration (NASA Goddard GEVS SE Rev A) | ||||||

| Mechanical Shock* | 100 G peak value (NASA GSFC S311-P-822) | ||||||

| * Testing was performed to determine if fretting occurs due to mechanical motion and to evaluate the integrity of the Hypertac contact system under severe shock. To validate the test, event detection was performed at 10 nanoseconds. There were no events recorded. ** Testing was performed using a 6U Flight Chassis to determine if fretting occurs due to mechanical motion and to evaluate the integrity of the test samples relative to severe mechanical environment. To validate the test, event detection was performed at 50 nanoseconds. There were no events recorded. |

|||||||

All specifications are subject to change without notice